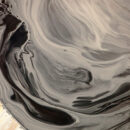

Drilling Fluid Recovery

Now you can reuse drilling fluid

R3's internationally recognized Vacuum Assisted Pure Oil Recovery technology has made it possible to recycle and reuse drilling fluid while generating almost no residual waste requiring landfilling or further treatment.

Purchase, transport, and dispose of less drilling fluid than ever by adopting a technology that is:

- Energy-efficient

- Portable, making it accessible for companies with remote exploration sites anywhere in the world

- Safe and easy to operate

About the technology

The Vacuum Assisted Pure Oil Recovery technology was conceived and developed as a safe, cost effective and robust solution to the problem of treating waste drilling mud and cuttings without thermally cracking or degrading the valuable synthetic drilling fluid. A secondary goal of the new technology was to minimize the generation of residual waste requiring additional treatment and/or disposal.

To achieve this, the technology utilizes a two-stage process that consists of 1) a low vacuum distillation unit (VDU) and 2) a pelletizing process to produce a product that can be utilized as an alternative industrial fuel source.

Recognized at the Offshore Technology Conference 2022

R3 Environmental Systems was recently announced as one of the 14 recipients of the 2022 Spotlight on New Technology™ awards. This prestigious award is presented by the Offshore Technology Conference (OTC)—a flagship industry event held annually in Houston, Texas, welcoming over 60,000 professionals from more than 100 countries every year.

The recipients of this year’s prestigious award were selected based on factors such as novelty in the marketplace, level of innovation, demonstrated success of the technology, broad commercial appeal, as well as the ability to make a significant impact across the offshore industry.

“This award is a tangible recognition for the time, patience and hard work from our team here at R3,” says Jerry Scott, General Manger, R3 Environmental Systems. “There is no handbook for creating something that doesn’t exist yet, so we are incredibly proud to have found a solution to a significant challenge in the oil and gas industry."